Why Winter Demands Extra Attention to Grease Trap Cleaning

Why Winter Demands Extra Attention to Grease Trap Cleaning

The Science: Why Grease Solidifies Faster in Winter

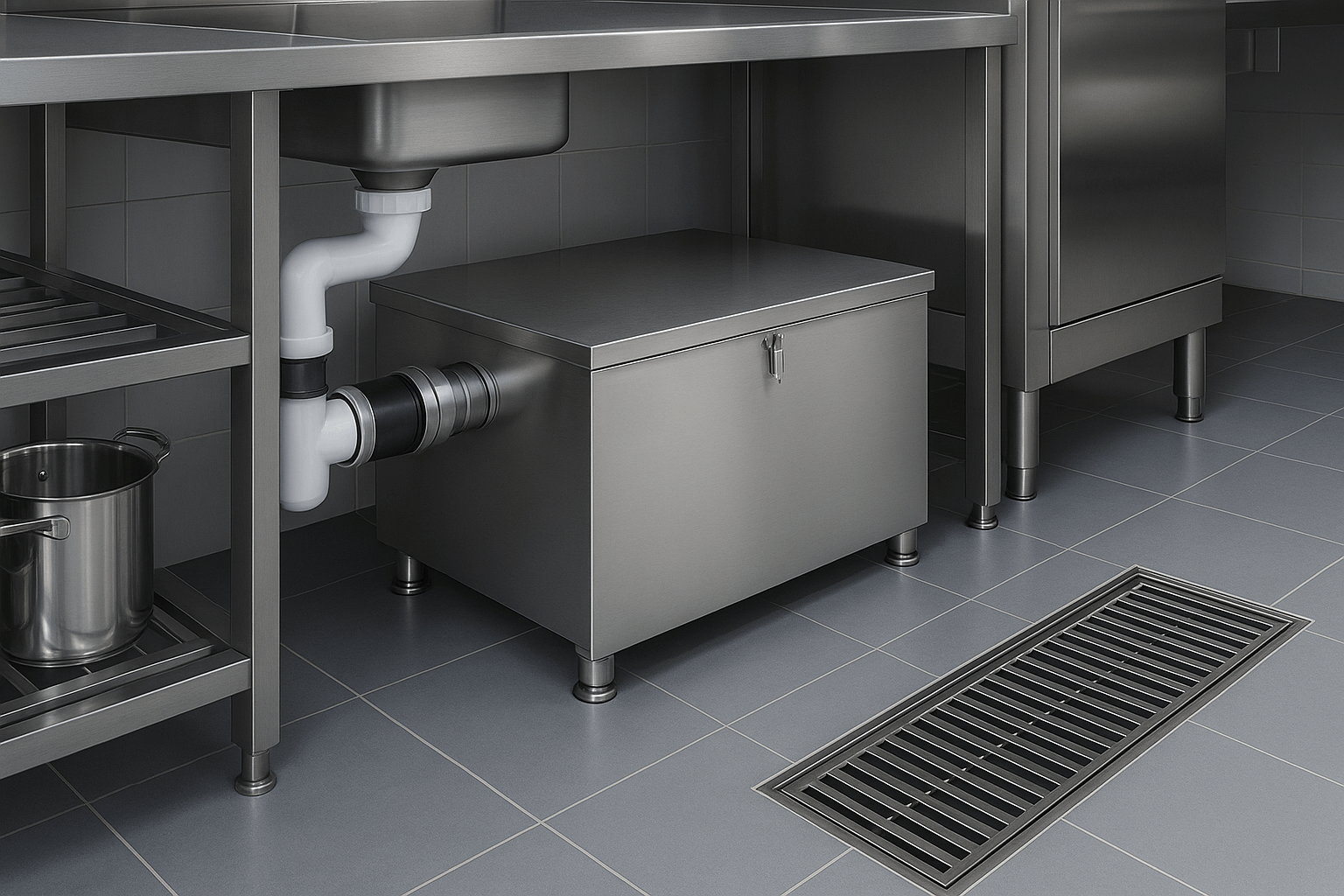

Fats, oils, and grease behave differently in colder temperatures. Normally, when hot wastewater from dishwashing or cooking flows through your grease trap, the FOG cools, separates, and rises to the top. But during winter, that cooling process accelerates—often before the grease can fully separate or flow through the system.

This results in:

-

Rapid build-up of solidified grease inside the trap

-

Clogged inlet/outlet pipes that restrict flow

-

Foul odours due to decomposing organic matter

-

Grease overflow that can contaminate drainage and even public sewers

Risks of Neglecting Winter Grease Trap Maintenance

Ignoring your grease trap during winter can lead to serious consequences:

-

Costly emergency call-outs to clear severe blockages

-

Plumbing damage from frozen or burst pipes clogged with grease

-

Fines or penalties for environmental violations

-

Disrupted operations, especially during peak service times

-

Long-term equipment damage from backflow or persistent pressure

Proactive Measures: How to Protect Your Business in Winter

Winter grease trap care doesn’t have to be complicated. It just needs to be consistent and proactive. Here’s what you can do:

1. Increase Cleaning Frequency

If your grease trap is normally cleaned every 3 months, consider switching to a monthly or bi-monthly schedule during winter. This prevents build-up from reaching critical levels.

2. Schedule Maintenance Before the Coldest Periods

Book professional servicing before winter hits hard. Preventative maintenance ensures your system starts the season in optimal condition.

3. Educate Your Staff

Train kitchen staff to avoid pouring fats or oils down sinks, especially in colder weather. Use grease containers and strainers to catch as much FOG as possible before it enters the plumbing.

4. Inspect for Blockages or Odours

Check your system regularly for any signs of slow drainage, gurgling noises, or unpleasant smells—these are early warning signs of a problem.

5. Consider Insulated or Heated Components

In extreme environments, installing heated grease trap lines or insulation around the trap can help reduce solidification within the system.

Why Professional Cleaning Is Non-Negotiable

Winter is no time to cut corners with maintenance. Hiring a professional grease trap cleaning service ensures:

-

Complete removal of solidified FOG and debris

-

Inspection of traps, lines, and flow levels

-

Documentation to meet health and safety compliance

-

Proper disposal of waste in accordance with local regulations

Most importantly, it prevents emergencies, protects your business reputation, and keeps your kitchen running smoothly, even in the coldest conditions.

Final Thoughts

When winter comes knocking, your grease trap shouldn’t be the weak link in your operation. The cold might harden fats, but it shouldn’t freeze your workflow.

By prioritising regular grease trap cleaning during winter, you’re not just preventing blockages, you’re investing in your business’s uptime, hygiene, and longevity.

Don't wait for a freeze to act. Book your winter grease trap servicing today and stay ahead of the cold-weather clogs.